We are manufacturers of stainless steel sheest, and have been in this business for many years. The stainless steel sheets that are manufactured and sold in an annealed or soft condition, is given a heating or annealing treatment to make sure, the stainless steel sheets are able to reinstate its originality or soft condition. Our stainless steel sheets are available in various grades, different finish, sizes, shapes and cuts, and can be custom made to, suit the client’s need.

Among all forms, the stainless steel sheet is on the whole, the most common. The stainless steel patta are used in manufacturing different types of products and also parts that have a lot of utility.

Let us make a list of the dominant advantages of stainless steel sheets.

• Resistance – Stainless steel sheets provide temperature and deterioration resistance, higher the grade of alloy, more the corrosion resistance, to acidic alkaline, and environment with chlorine bearing.

• Heat resistance – Our stainless steel patta is made of high chromium alloyed grades and exact nickel helping it to retain its strength and making it resistant to scaling, in an environment where heat and corrosion is very high, like the petrochemical, automobile, oil and chemical industry.

• Artistic value - stainless steel patta has a striking image and a pleasing appearance.

• Strength – Stainless steel has good strength and high robustness.

• Cost effective – Stainless steel patta has an even surface finish for easy cleaning, leading to less maintenance.

• Fabricate - Stainless steel can be cut, welded and fabricated to form conventional and simple sheets.

• Impact – Stainless steel sheet is suitable for cryogenic applications. The austenitic microstructure of stainless steel 300 series can handle the temperature from hot to cool.

• Recycle - Stainless steel is eco friendly.

• Sustainability – The numerous factors that make stainless steel highly sustainable are recapturing the rates, recycle, heat resistance, long term services, anti corrosion and toughness.

Stainless steel sheets can be used for machinery in factories. Also, for tanks and equipments required for the manufacturing process.

Used for architectural purposes, as decoration on majestic buildings or beautiful homes, on escalators and in the door of an elevator.

Stainless steel sheets are handy and used for medical equipments. Medical industry uses stainless steel to maintain an antiseptic environment.

Used in consumer products, kitchenware and household appliances, like, microwave, cooking stove, etc.

Also used in construction, automobiles, food process and storage.

The stainless steel patta process includes, cutting, next machining or drilling, then grinding and lastly, testing.

The stainless steel patta that we manufacture is from a stainless steel billet, it is then converted into a stainless steel flat with the help of hot and cold rolling, this leads to stainless steel sheets of various width and length.

The stainless steel patta that we manufacture are slightly oval at the end and can be cut from the length to meet the customized requirement of the customer.

We also use stainless steel patta to make pipes of different diameter and thickness; these pipes are either given a bright mirror finish or another finish. All of this is directly related to the customer’s need.

The first series in stainless steel is the 200 series, that used manganese, instead, of nickel, because manganese was less expensive. Because of low nickel content, the 200 series is cheaper than 304 series. It is found in cooking utensils, tanks for water storage, equipments, etc.

The 201 series contains nitrogen, more manganese and less of nickel. It is cost effective, was initially developed to preserve nickel, a good substitute for 301, used in architecture, railways, kitchen sink, car roof, etc.

The 202 grade of stainless patta can be converted into sheets, coils or plates that can be used in kitchen sinks, house windows and doors, railways, clamps for hose pipes, etc.

Grade 203 can act as an alternative for grade 303, because of high copper and manganese; it can substitute nickel, known for sturdiness and has good strength and rust resistance. Used in restaurants, automobile industry, trailers, etc.

Series 304 has some great features, such as, rich in nickel, has right properties for welding, rust resistance, known for sturdiness and easy to manufacture and clean. It is used for various household and industrial applications, like pipes, sterilizers, containers, water filtration, medical care, hotels and many more. 304 series is eye-catching with a spotless finish and less maintenance, it is a common form of stainless steel across the globe, and has an outstanding deterioration resistance and great value.

Stainless steel coil is a finished product that belongs to the stainless steel family; it is coiled or curled after rolling. Professionals and latest technology, has made stainless steel coil ideal for numerous applications, it can be seen in the construction of roads, bridges, pipes and structures. These stainless steel coils are available in different dimensions to meet the requirement or need of the client. Stainless steel coil is known for rust and high temperature resistance, good strength, toughness, recycle and workability. The stainless steel coil is made, by putting together diverse stainless steel grades, to meet the need of the client. These steel coils have been classified into stainless steel coil or hot rolled and cold rolled coil and carbon coil. The latest add on is the galvanised steel.

Hot rolled coil – A product that is semi finished, where the steel is rolled at a very high temperature, this helps in giving it a shape and in plummeting the thickness to a certain limit. Hot rolled coil is cost effective because there is never a delay in the manufacturing process. Hot rolled coil is used in construction, pipes, welding and tanks. It is ideal where exact shape is not needed.

Cold rolled coil – Processing hot rolled coil further leads to cold rolled coil. The process starts with steel sheet passing through reduction mill, then comes annealing and last, rolling. Cold rolling coil is a complete product; it has surfaces with good finish, accurate in size, good tolerance and is tough. It is seen in automobiles and household appliances.

The process starts with recycling of used stainless steel. The recycled stainless steel and original steel will have similar features and virtues. Before, the melt shop, the steel needs to be tested. First, the raw materials are melted in EAF (electric arc furnace. Then, carbon, nitrogen and sulphur are removed. In a ladle treatment, need to tune the temperature and composition of steel. Next step is where the solid molten steel is cut into slabs. These slabs are of great quality and have an identity number, making it easier to track.

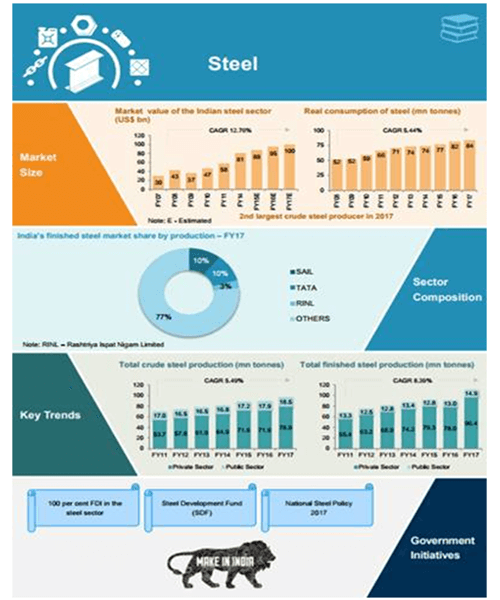

Let’s look into the market standing of stainless steel and stainless steel coil,

Exports - The export from India for Hot rolled coil is 1364.21 tonnes and for cold rolled coil is 955.60 tonnes. The major ports that export these coils are Goa, Vizag, Magdalla, Kolkata and Nhava Sheva.

Market share - Stainless steel coil has a good market share of the world’s stainless steel industry. The revenue accounts to 73.4% in the world market.

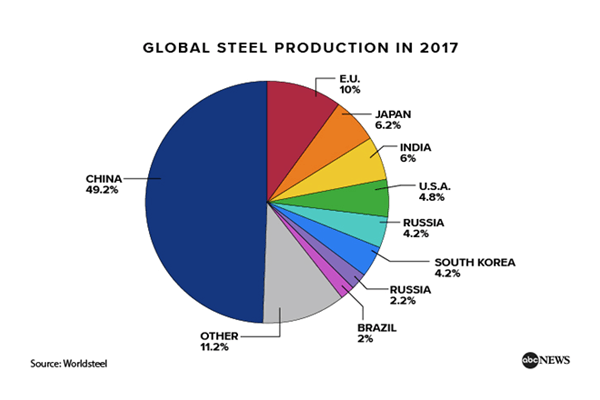

Ranking and Production - India ranks among the top ten, in the production of stainless steel, in the world market, China ranks first on the chart.

The domestic production of stainless steel reached 3.6 million tonnes, a 9% increase. Globally, India exported about 10 million metric tons of steel, a 38% rise.

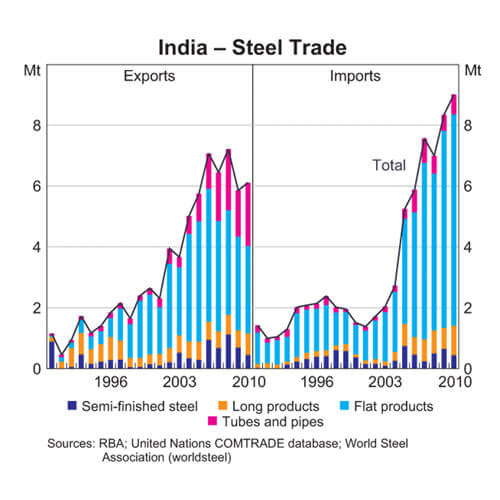

Graph showing steel trade

For a customized coil,

Slitting is a process where coils or rolls are cut, with the help of very pointed blades. Generally, these slitters are well-resourced with different knives. With advancement in technology, slitting line is able to produce high quality and tough coils. Slitting process is flexible and can provide customized coils.

The main focus for stainless steel is automobile industry, kitchen appliances, medical, construction and energy.

For stainless steel coil, the target is, power plants, drilling, pumps, pharmaceutical, paper and pulp, ship building, aerospace, architecture, research and technology, biochemistry, water treatment plant, drilling and environmental technology.

Steels with Cr-Mn-Ni-N composition were called 200 Series of Stainless Steel. The principle difference between 300 series of Stainless Steel and this series was that the Nickel used in 300 series of Stainless steel was partly replaced by Manganese and Nitrogen. Nickel being a costly metal, the obvious advantage of 200 series was cost effectiveness.

During period of Nickel shortage 200 series of Stainless Steel have been used across the board to replace 300 series of Stainless Steel with only minor design and fabrication adjustments.

It was found that 200 Series have 40% higher yield strength than 300 series. The physical and mechanical properties of both series are quite compatible. 200 series also has additional component of Carbon, which gives higher effectiveness to the austenitic nature of Stainless Steel.

201 and 202 stainless steels have properties similar to 301 and 302 series in annealed and cold rolled conditions and perform similarly. This steel can be formed in the same equipment that is used for 300 series with the same lubricants and annealed tempers of this Cr-Mn-Ni-N steel is much suitable for deep drawing.

304 Stainless Steel is used in a kitchen utensil to a nuclear reactor. 201 has comparable properties for kitchen utensil application. 200 Series has been used in variety of applications in India for nearly 10 years running into a production statistics of 200000 MT in 1988 to 600000 MT in 1999.

Usage of 201 will give much higher value for money because of lower initial cost for the suggested application.

Thus other things being equal cost effectiveness of 200 series, leads to the conclusion that it is preferable to use 200 series of Steel over 300 series.

200 Series of Stainless steel is produced using the same methods as for 300 Series and by using the same machineries. The temperature range used is also the same.

However 200 Series steel has 40% higher yield than corresponding 300 series stainless steel. Also Manganese and Nitrogen which are cheaper replaces Nickel, which is the costlier material.

Thus 200 series of Stainless steel are cheaper than 300 series of steel.

No. This material gets an economic advantage by redesigning the chemistry and achieving the relevant properties for utensil manufacture comparable to 304 Grade SS. Therefore this is not by sacrificing quality.

Austenitic structure confers valuable properties, which enable Stainless steel to be cold worked. Cold drawn and deformed into any shape required by process industries. Austenitic steels have good resistance to corrosion and oxidation and can be used for variety of applications involving handing of chemicals and in processing industries. Materials like Nickel, Manganese, Nitrogen stabilizes this austenitic nature of steel. Manganese is a weak stabilizer than Nickel and Nitrogen is stronger to Nickel.

| Grade | S14 |

|---|---|

| C | 0.07-0.09 |

| Mn | 9.2 - 9.4 |

| Si | 0.4 - 0.6 |

| P | 0.0075 |

| S | 0.015 |

| Ni | 0.75-0.95 |

| Cr | 14.8-15.2 |

| Cu | 1.7 - 1.9 |

| N2 | 1550-1750 |

Chromium is the alloying element that imports to stainless steels their corrosion resistance qualities. It does this by combining with oxygen to form a thin, transparent chromium oxide protective film on the metal surface.

The chromium oxide film is stable and protective in normal atmospheric or mild aqueous environment and it can be improved by higher chromium, by nickel and molybdenum and/or other alloying elements.

Chromium improves film stability, chromium and molybdenum increases resistance to chloride penetration and nickel improves film resistance in acidic environments.

In the event that the protective film is distributed or destroyed, in the presence of oxygen in the environment it reforms itself and continues to provide protection

Corrosion resistance is dependant on Chromium and the degree of polish obtained. As far as Chromium is concerned the free Chromium oxide film which is impervious for corrosion attack.As its well known carbon can combine with 17 times its own weight of chromium helps to achieve to form carbides. In this case this works out 0.09 x 17 = 1.53. The minimum Chromium maintained in these Steel is 14.5% so the recommended level of atmospheric conditions the chromium does not play any significant role in Corrosion resistance.

So the Carbon content does not affect Chromium content much and thus does not affect corrosion resistance properties.

Copper is in solid solution in austenite and the level maintained in this type of Steel is only 1.8%, which is much lower than the solubility limit of Copper which is 4%.

Thus there is no evidence of adverse effect due to presence of Copper.

Nickel does not directly contribute to corrosion resistance, under normal conditions. It only helps to stabilize the austenitic structure, improve formability characteristics and heat resistant characteristics.

In this case the austenite stability is achieved through higher Manganese and Nitrogen (Austenite stabilizes) and formability is achieved through controlled addition of Copper. Therefore lower Nickel does not result in any negative factor.

Materials like Nickel, Manganese, Nitrogen stabilizes this austenitic nature of steel. Manganese is a week stabilizer than and Nitrogen is stronger to Nickel.0.26% of Nitrogen can replace 8% Nickel 4-7% Nickel is replaced by 7-10% of Manganese and some Nitrogen and achieve clean steel.

Circles and Sheets are produced the same way but the advantage of circles being that they produce less scrap material as compared to sheets. Most of the vessels and utensils (which are made from this material) are of circular shape hence even from the sheets, circle needs to be cut, thus producing scrap material. This scrap material produced has no resell value and can only be junked.

Thus using circles over sheets one can reduce the actual cost.

The equipments used for 304 can also be used for 203 including the lubricating however we advice the following guidelines to be followed:

Deep drawing ratio : 2

Elongation by spinning : 30%

Production sequence in one go

All welding equipments same as 304 Grade can be used.

The chemistry offered is derived form the parent AISI 200 series, with suitable technical modification to achieve the final properties in a cost effective manner as compared to the existing 304 Grade SS. Literature survey reveals that AISI 200 series were developed in 1950's in the United States, that development was strictly by the nickel shortage which was prevalent at that time. The composition of these Steels varied widely with carbon ranging from 0.08 to as high as 0.25%, nickel from 0.3 to around 7 % , Nitrogen from 0.10 to 0.4% with a chromium level of 14 to 18%. The technical theme behind development of these grades was mainly to substitute the costly nickel with manganese and nitrogen to achieve the austenitic structure by controlling the ratio of austenite forming elements and ferrite forming elements (Ferrite Factor) The drawbacks with these steel were higher carbon (>0.1%) and higher nitrogen resulting into poor formability characteristics. With these backgrounds a new chemistry was designed in which the carbon is controlled to a maximum level of 0.09% and nitrogen up to 1700ppm to aid in formability addition Copper is made so that the work hardening rate is controlled. Thus the optimized chemistry offered by us is

Grade |

SI4 |

S |

0.015 |

C |

0.07-0.09 |

Ni |

0.75-0.95 |

Mn |

9.2-9.4 |

Cr |

14.8-15.2 |

Si |

0.4-0.6 |

Cu |

1.7-.9 |

P |

0.075 |

N2 |

1550-1750 |

Physical Properties of annealed AISI 200 Series |

||

Destiny |

gr/cu.cm |

7.74 |

|

ib/cu.in |

0.28 |

Thermal |

20-100°C Cal/cm/sec/°C/cm |

0.039 |

Conductivity |

68-212°C Btu/ft2/hr/°F/ft |

9.4 |

Specific Heat |

0-100°C Cal/gm/°C |

0.122 |

|

32-212°F Btu/ib/°F |

0.12 |

Coefficient of |

20-100°C cm/cm/°C |

16.6*10^-6 |

Thermal |

68-212°F in/in/°F |

9.2*10^-6 |

Expansion |

20-316°C cm/cm/°C |

18.0*10^-6 |

|

68-600°Fin/in/°F |

10.0*10^-6 |

|

20-538°Ccm/cm/°C |

19.6*10^-6 |

200 Series |

300Series |

|

0.2% proof stress(kg/mm2) |

35.5 |

26.7 |

Tensile Strength (ksi) |

85-115 |

75-85 |

Elogation |

45-55 |

40 |

Yield Stress (ksi) |

50 |

35 |

GSN |

8-9 |

7.8 |

Hv |

208 |

157 |

Erchsen value |

12.5 |

12.9 |

Limited Drawing Limit |

2.0 |

2.3 to 2.5 |

Considering that the components manufactured out of these sheets are used in normal atmospheric condition chromium level 14.5% to 25.5% is quite to resist pitting corrosion. Experiment carried out showed the following result

Kitchen utensils and cutleries retained their surface finish and luster similar to 304 Grade

Laboratories scaled experiments carried out under different media revealed the following data

Corrosion rates of the Stainless Steels Fully Immersed in 3% Sodium Chloride

B>Stainless |

Temperature |

Duration |

B>Corrosion |

B>Visual |

|

°K |

°C |

(Hour) |

B>x 10^- |

||

J |

303±2 |

30±2 |

720 |

2.58 |

Localised |

S |

303±2 |

30±2 |

720 |

3.29 |

Localised |

J |

371±2 |

98±2 |

100 |

0.25 |

Material Remained |

B>Stainless |

Temperature |

|

Duration |

Corrosion |

B>Visual |

°K |

°C |

(Hour) |

B>x 10^- |

||

J |

303±2 |

30±2 |

720 |

0.44 |

Fungal growth |

S |

303±2 |

30±2 |

720 |

0.38 |

Fungal growth |

J |

371±2 |

98±2 |

100 |

0.34 |

Material Remained |

S |

371±2 |

98±2 |

100 |

0.17 |

Material Remained |

SS |

B>Temp |

B>Duration |

Elements estimated by AAS (ppm) |

|||||

Fe |

Cr |

Cu |

Mn |

Ni |

Ti |

|||

J |

30±2 |

720 |

0.177 |

0.011 |

0.003 |

0.508 |

- |

- |

S |

30±2 |

720 |

0.157 |

0.048 |

0.024 |

0.48 |

- |

- |

J |

98±2 |

100 |

0.057 |

0.007 |

0.015 |

0.829 |

- |

- |

S |

98±2 |

100 |

0.010 |

0.012 |

0.028 |

0.035 |

- |

- |

The blanks cut from the annealed sheets respond favorable to the commonly fabrication operation such as deep drawing, spinning, welding, bidding, rib formation, embossing, electro deposition of metal like copper and necking of cylindrical parts. The quantified data on formability is given bellow: Limited Drawing Ration - 2 Percentage Stretch in Spinning - 30% Erichsen Value - 12.5

Note : Information in this document is only for the explanation of general characteristics and properties of our product. For requirement of exact report you should contact our technical department for same.

"Nothing is good or bad but thinking make it so" - Shakespeare

A number of grade of 200 series stainless steel have been developed subject to extensive testing in india, which contain Chromium in the range of 14.0-16.0 % and nickel in the range of 0.3 - 4 % along with appropriate content of Manganese, Copper, Nitrogen.

S.S.200 series exhibit good strength and formability. they possesses good corrosion resistance properties

These grades have austenitic structure similar to 300 series Stainless steel, exhibit high strength and good formability. they are suitable for versatile stainless steel application. and above all they are more cost effective.

S.S.200/ KS7 and KS6 Grade can be used for flatware / shallow draw. S.S.200/ KS4 can be used for deep draw items S.S.200/ KS3 and KS1 are still softer can be used for extra deep draw items.

At present 70000 tons of S.S. 200 is produced in India / month out of which approximately 30,000 tons of S.S.200 is exported from India in form of hr coil, sheet, circle and kitchenware

|

|

KS1 |

KS2 |

KS3 |

KS4 |

KS5 |

KS6 |

KS7 |

Carbon |

C |

0.09 |

0.09 |

0.09 |

0.09 |

0.09 |

0.09 |

0.09 |

Manganese |

Mn |

8.0/9.5 |

8.0/9.5 |

8.0/9.5 |

8.0/9.5 |

8.0/9.5 |

8.0/9.5 |

8.0/9.5 |

Silicone3 |

Si |

0.4 |

0.4 |

0.4 |

0.4 |

0.4 |

0.4 |

0.4 |

Chromium |

Cr |

15/16 |

15/16 |

14/15 |

14/15 |

13/14 |

13/14 |

13 |

Nickel |

Ni |

4% |

3% |

1.9/2% |

1/1.2% |

0.7/0.8% |

0.5/0.6% |

0.3/0.5% |

Molybdenum |

Mo |

0.2 |

0.2 |

0.2 |

0.2 |

0.2 |

0.2 |

0.2 |

Phosphorus |

P |

0.08 |

0.08 |

0.08 |

0.08 |

0.08 |

0.08 |

0.08 |

Sulphur |

S |

0.01 |

0.01 |

0.01 |

0.01 |

0.01 |

0.01 |

0.01 |

Copper |

Cu |

1.6 |

1.6 |

1.6 |

1.6 |

1.6 |

1.6 |

1.6 |

Note: The above is spectro reading and there can be variation +/- 5% in retest

Tensile Strenth (UTS) - 115 N/mm2

Yield Stress N/mm2 - 65Ksi

Elongation( % ) - 40 TO 45 %

Product |

Thickness |

Length |

Width (size) |

Surface Finish |

Edge |

||||

Available Range |

Tolerance |

Available Range |

Tolerance |

Available Range |

Tolerance |

||||

Sheet |

0.35 - 1.50 |

± 0.03 |

2400 |

± 150 |

250 - 600 |

± 5 |

2 B / 2 D (Cold rolled Annealed and Pickled) |

Mill Edge |

|

1.51 - 2.00 |

± 0.03 |

1800 |

± 150 |

||||||

Blank |

0.35 - 1.50 |

± 0.02 |

2400 |

± 1 |

Max. 600 |

±1 |

Sheared Edge |

||

Circle |

0.35 - 1.50 |

± 0.02 |

- |

± 1 |

Ø Max. 600 |

± 1 |

Sheared Edg |

||

We would take this opportunity to introduce ourselves as manufacturer and Exporter of Stainless Steel Sheets / Circles (Not Coils) Pipe, Brightbars in 200 Series/304 Series and Kitchenware like Bowls, Stock pots, Pots, Pans, Fabricated pots, Trays, Dishes, Sinks, Special items as per customers requirement.

200 Series S.S. Sheets / Circles are having wide acceptability against 304 series steel for manufacturing of KITCHENWARE items / FLATWARE like Stock Pots, Pans, Bowls, Tea pots, Trays, Spoons, Forks etc. In India, 20000tons of S.S.-200 Kitchenware is exported per month in form of sheet circle and kitchenware.

S.S. 200 is having all the features of stainless steel like non-corrosive, non-magnetic and attains bright finish on polishing.

At present, our S.S.-200 Sheets / Circles are being exported to China, Hong Kong, Philippines, Syria, Egypt, Vietnam, South America, South Africa, UAE, Iran, Indonesia, Malaysia, Turkey, Pakistan, Bangladesh etc.

We would request you to please let us know if you have some interest / requirement in using 200 series Steel for your end products.

STAINLESS STEEL CHEMICAL COMPOSITION |

|||||||||||||||||||||

S.S. |

200 |

202 |

301 |

302 |

302B |

303 |

303Se |

304 |

304L |

305 |

308 |

309 |

309s |

310 |

310s |

314 |

316 |

316L |

317 |

321 |

347 |

Carbon |

0.12 |

0.12 |

0.15 |

0.15 |

0.15 |

0.15 |

0.15 |

0.08 |

0.03 |

0.12 |

0.08 |

0.20 |

0.08 |

0.25 |

0.08 |

0.25 |

0.08 |

0.03 |

0.08 |

0.08 |

0.08 |

Manganese |

7.5/10 |

5.5/7.5 |

2.00 |

2.00 |

2.00 |

2.00 |

2.002.00 |

2.00 |

2.00 |

2.00 |

2.00 |

2.00 |

2.00 |

2.00 |

2.00 |

2.00 |

2.00 |

2.00 |

2.00 |

2.00 |

2.00 |

Silicone |

0.9 |

0.9 |

1.00 |

1.00 |

2.0/3.0 |

1.00 |

1.00 |

1.00 |

1.00 |

1.00 |

1.00 |

1.00 |

1.00 |

1.5 |

1.5 |

1.5/3.0 |

1.00 |

1.00 |

1.00 |

1.00 |

1.00 |

Chromium |

14/16 |

16/18 |

16/18 |

17/19 |

17/19 |

17/19 |

17/19 |

18/20 |

18/02 |

17/19 |

19/21 |

22/24 |

22/24 |

24/26 |

24/26 |

24/26 |

23/26 |

16/18 |

18/20 |

17/19 |

17/19 |

Nickel |

0.5/2.0 |

0.5/4.0 |

6.0/8.0 |

8.0/10 |

8.0/10 |

8.0/10 |

8.0/10 |

8.0/12 |

8.0/12 |

10/13 |

10/12 |

12/15 |

12/15 |

19/22 |

19/22 |

19/22 |

10/14 |

10/14 |

11/15 |

9.0/12 |

9/13 |

Molybdenum |

0.2 |

0.2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2.0/3.0 |

2.0/3.0 |

3.0/4.0 |

|

|

Phosphorus |

0.06 |

0.06 |

0.045 |

0.045 |

0.045 |

0.20 |

0.20 |

0.045 |

0.045 |

0.045 |

0.045 |

0.045 |

0.045 |

0.045 |

0.045 |

0.045 |

0.045 |

0.045 |

0.045 |

0.045 |

0.045 |

Nitrogen |

0.25 |

0.25 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Suiphur |

|

|

0.03 |

0.03 |

0.03 |

0.15MIN |

- |

0.03 |

0.03 |

0.03 |

0.03 |

0.03 |

0.03 |

0.03 |

0.03 |

0.03 |

0.03 |

0.03 |

0.03 |

0.03 |

0.03 |

Selenium |

|

|

|

|

|

|

0.15MIN |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Aluminium |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Titanium |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5XC |

|

Cb+Ta |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10XC |

Tensile |

105 |

105 |

110 |

90 |

95 |

90 |

90 |

85 |

60 |

85 |

85 |

90 |

90 |

95 |

95 |

100 |

85 |

78 |

90 |

87 |

92 |

2% Yield |

55 |

55 |

40 |

37 |

40 |

35 |

35 |

35 |

30 |

37 |

35 |

40 |

40 |

40 |

40 |

50 |

35 |

30 |

40 |

35 |

35 |

Elongation |

55 |

55 |

60 |

55 |

50 |

50 |

50 |

55 |

55 |

55 |

55 |

45 |

45 |

45 |

45 |

45 |

55 |

55 |

50 |

55 |

50 |

Rockwell |

90 |

90 |

85 |

82 |

85 |

84 |

84 |

80 |

76 |

82 |

80 |

85 |

85 |

87 |

87 |

87 |

80 |

76 |

85 |

80 |

84 |

Brinell |

185 |

185 |

165 |

155 |

165 |

160 |

160 |

150 |

140 |

156 |

150 |

165 |

165 |

170 |

170 |

170 |

150 |

145 |

160 |

150 |

160 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

En58M |

|

En58E |

150-801C |

|

|

|

|

|

|

|

|

|

En58J&H |

|

|

En58C |

|

|

|

|

X12 |

X2 |

|

|

|

X5 |

X5 |

X12 |

|

|

|

|

|

|

x5 |

X2 |

X10 |

|

|

|

AUST. |

|

AUST. |

AUST. |

AUST. |

AUST. |

AUST. |

AUST. |

AUST. |

AUST. |

AUST. |

AUST. |

AUST. |

AUST. |

AUST. |

AUST. |

AUST. |

AUST. |

AUST. |

AUST. |

AUST. |

CHEMICAL COMPOSITION OF AISI WROUGHT STAINLESS STEELS |

||||||||||||||||||

Physical corrosion resistance & other properties of important S.S.Grades |

||||||||||||||||||

S.S.Grade |

201 |

202 |

301 |

302 |

304 |

304L |

309 |

309S |

310 |

310S |

316 |

316L |

321 |

347 |

409 |

430 |

434 |

410 |

Density |

7.9 |

7.9 |

8.0 |

8.0 |

8.0 |

8.0 |

8.0 |

8.0 |

8.0 |

8.0 |

8.0 |

8.0 |

8.0 |

8.0 |

7.7 |

7.8 |

7.8 |

7.8 |

Sp.Elec. Resist 20C micro |

72 |

72 |

72 |

72 |

72 |

72 |

78 |

78 |

78 |

78 |

74 |

74 |

72 |

73 |

60 |

60 |

60 |

57 |

Sp. Heat (0-100c) |

0.5 |

0.5 |

0.5 |

0.5 |

0.5 |

0.5 |

0.5 |

0.5 |

0.5 |

0.5 |

0.5 |

0.5 |

0.5 |

0.5 |

46 |

46 |

46 |

46 |

Ther. Conductivity |

16.3 |

16.3 |

16.3 |

16.3 |

16.3 |

16.3 |

14.2 |

14.2 |

14.2 |

14.2 |

16.3 |

16.3 |

16.3 |

16.3 |

25.1 |

26.0 |

26.0 |

25.1 |

|

15.7 |

18.4 |

17.0 |

17.2 |

17.3 |

17.3 |

15.0 |

15.0 |

15.9 |

15.9 |

15.9 |

15.9 |

16.6 |

16.6 |

11.7 |

10.4 |

11.9 |

9.9 |

Mild water |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

Industrial |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

|

X |

X |

|

Marine |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

|

|

X |

|

Salt Water |

|

|

|

|

|

|

|

|

|

X |

X |

|

|

|

|

|

|

|

Mild |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

Oxidising |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

|

X |

X |

|

Reducing |

|

|

|

|

|

|

|

|

|

|

X |

X |

|

|

|

|

|

|

Abrasion Resistance |

Good |

Good |

Good |

Good |

Good |

Good |

Good |

Good |

Good |

Good |

Good |

Good |

Good |

Good |

Good |

Good |

Good |

Good |

Cold Forming |

Fair |

Good |

Good |

Excel |

Excel |

Good |

Good |

Good |

Good |

Good |

Good |

Good |

Good |

Good |

Fair |

Fair |

Fair |

Fair |

Weldability |

Good |

Good |

Excel |

Excel |

Excel |

Excel |

Good |

Excel |

Good |

Excel |

Excel |

Excel |

Excel |

Excel |

Fair |

Fair |

Fair |

Fair |

Melting Flange |

1400 1420 |

1400 1450 |

1370 1400 |

1400 1430 |

1430 1510 |

1480 1530 |

||||||||||||

Scaling Temp |

800 |

800 |

800 |

900 |

900 |

900 |

1100 |

1100 |

1100 |

1100 |

900 |

900 |

900 |

900 |

700 |

800 |

800 |

700 |

Weight of S.S. Sheets & Plates ::

Length ( Mtrs ) X Width ( Mtrs ) X Thick ( MM ) X 8 = Wt. Per PC

Length ( fit ) X Width ( Mtrs ) X Thick ( mm ) X ¾ = Wt. Per PC

Weight of S.S. Circle ::

Dia ( mm ) X Dia (mm ) X Thick ( mm ) / 160 = Gms. Per PC

Dia ( mm ) X Dia (mm ) X Thick ( mm ) X 0.00000063 = Kg. Per PC.

Weight of S.S. Pipe

O.D. ( mm ) – W Thick ( mm ) X W.Thick ( mm ) X 0.0248 = Wt. Per Mtr.

O.D. ( mm ) – W Thick ( mm ) X W.Thick ( mm ) X 0.00758 = Wt. Per Mtr.

Weight of S.S. Round Bar.

Dia ( mm ) X Dia (mm ) X 0.00623 = Wt. Per. Mtr.

Dia ( mm ) X Dia (mm ) X 0.0019 = Wt. Per. Feet.

Weight of S.S. Square Bar.

Dia ( mm ) X Dia ( mm ) X 0.00788 = Wt. Per. Mtr

Dia ( mm ) X Dia ( mm ) X 0.0024 = Wt.Per. Feet.

Weight of S.S. Hexagonal Bar

Dia ( mm ) X Dia ( mm ) X 0.00680 = Wt. Per.Mtr

Width ( mm ) X Dia ( mm ) X 0.002072 = Wt. Per Feet

Weight of S.S. Flate Bar

Width (mm ) X Thick ( mm ) X 0.00798 = Wt.Per Mtr.

Width (mm ) X Thick ( mm ) X 0.00243 = Wt.Per Feet.

Weight of Brass Pipe / Copper Pipe

O.D. ( mm ) – Thick ( mm ) X Thick (mm ) X 0.0260 = Wt. Per Mtr.

Weight of Lead Pipe.

O.D. ( mm ) – Wt ( mm ) X Wt ( mm ) X 0.0345 = Wt. Per Mtr.

Weight of Aluminium Pipe

O.D. ( mm ) – Thick ( mm ) X Thick ( mm ) X 0.0083 = Wt.Per. Mtr.

Weight of Aluminium Sheet

Length ( Mtr ) X Width ( Mtr ) X Thick ( mm ) X 2.69 = Wt.Per PC

Weight of Conversion of Mtr to Feet

Wt of 1 Mtr. 3.2808 = Wt.Per Feet.

Barlow’s Formula for calculating bursting pressure

P = 2ST/Dort – DP/2S or S – DP/2t or D = 2st/p

P = Bursting Pressure P. si.

S = Tensile Strength of tube.

T = Well Thickness ( In Inches )

D = Outside diameter ( In Inches ).

Due to its goods formability and corrosion resistance properties it can be used in the following.

Deep draw utensils, Water filters, Storage vessels, Milk cans, Kitchen sinks. Shallow/Medium draw Utensils, Tableware, Cutlery, Stands for Water Filters, Water tanks, Flasks, Dog pots.

Spin drives of washing machines, microwave ovens, Dishwasher, Thermo ware, Decorative trims, Steel Furniture, Fruit stands, Flower vases, Gift items, Thermo-ware, Gas stoves.

Door and windows frames, Column claddings, Street furniture, Bus shelters, Telephone booths, Pipes and Tubes, Ornamental tubes. Handrails, Street furniture, Door hinges/knob, Pipes and tubes ornamental Tubes.

Automotive trims, Wheel caps, Wiper arms, Rims, Auto accessories S.S.200 should not be used for external application in coasted areas and is also not recommended for storage of acid and other highly corrosive industrial chemicals.

AISI AND SAE STAINLESS STEEL STANDARDS |

|||||||||||

|

USA |

West Germany |

Great Britain |

Poland |

Romania |

Soviet Union |

Sweden |

||||

AISI |

SAE |

Standard No. |

Din |

BS970:part |

En steel |

Spec.No.PN |

Type |

Spec.No.Stas |

Type |

Gost |

SIS-14 |

201 |

|

|

|

|

|

|

|

3583 |

10AzMNC170 |

|

|

202 |

|

14371 |

XBCrMnNi189 |

284S16 |

|

66020 |

OH17N4G8 |

|

|

12Kh17G9AN4 |

|

301 |

30301 |

14310 |

X12CrNi177 |

301S21 |

|

|

|

|

|

|

|

302 |

30302 |

14300 |

X12CrNi188 |

302825 |

58A |

86020 |

IH18N9 |

3583 |

10Nc180 |

12Kh18N19 |

2330 |

|

|

|

|

|

|

|

|

|

|

|

2331 |

302B |

30302B |

14330 |

|

|

|

|

|

|

|

|

|

303 |

30303 |

14305 |

X12CrNis188 |

303S21 |

58M |

|

|

|

|

|

2346 |

303SE |

30303Se |

14305 |

X12CrNis188 |

303S41 |

58M |

|

|

|

|

|

2346 |

304 |

30304 |

14301 |

X5CrNi189 |

304S15 |

58E |

86020 |

OH18N9 |

3583 |

7NC180 |

08Kh18N10 |

2332 |

|

|

|

|

|

|

|

|

|

|

|

2333 |

304L |

30304L |

14306 |

X2CrNi189 |

304S15 |

|

86020 |

OOH18N10 |

|

|

|

2352 |

309 |

30309 |

14828 |

X15CrNiS12012 |

309S24 |

|

86022 |

H20N13S2 |

3583 |

155NC200 |

20Kh20N14S2 |

|

309S |

30309S |

|

|

|

|

|

|

|

|

|

|

310 |

30310 |

14841 |

X15CrNiS12012 |

309S24 |

|

86022 |

H2ON13S2 |

3583 |

155NC200 |

20Kh20N14S2 |

|

310S |

30310S |

14845 |

14845X5CrNi2521 |

|

|

86022 |

H23N18 |

|

|

|

156 |

2361 |

|

|

|

|

|

|

|

|

|

|

|

316 |

30316 |

14401 |

X5CrNiMo1810 |

316S16 |

58J |

|

|

6855 |

T12MSMoNC180 |

|

2347 |

|

|

|

|

|

|

|

|

|

|

|

2343 |

316L |

30316L |

14404 |

X2CrNiMo1810 |

316S12 |

|

86020 |

OOH17N14M2 |

|

|

|

2353 |

317 |

30317 |

14449 |

X5CrNiMo1713 |

317S16 |

|

|

|

|

|

|

|

317L |

|

14435 |

X2CrNiMo1812 |

317S12 |

|

|

|

|

|

03CH17N14M2 |

|

321 |

30321 |

14541 |

X10CrNiTi180 |

321S20 |

|

|

OH18N9T |

3583 |

7TNC180 |

1Kh18N1oT |

2337 |

|

|

|

|

321S12 |

58B&58G |

86020 |

OH18N10T |

|

|

|

|

347 |

30347 |

14550 |

X10CRNiNb189 |

347S17 |

58F&58G |

86020 |

OH18N12Nb |

3583 |

12C130 |

12Kh13 |

2302 |

403 |

51403 |

14006 |

X10Cr13 |

403S17 |

|

|

|

3583 |

12C130 |

12Kh13 |

2302 |

405 |

51405 |

14002 |

X7CrA113 |

|

|

86020 |

OH13J |

|

|

|

|

410 |

51410 |

14006 |

X10Cr13 |

410S21 |

5A |

|

|

3583 |

12c130 |

12Kh13 |

2302 |

414 |

51414 |

|

|

|

|

|

|

|

|

|

|

416 |

51416 |

14006 |

X10cR13 |

416S21 |

56AM |

|

|

|

|

|

|

416Se |

51416Se |

|

|

416S41 |

56AM |

|

|

|

|

|

|

420 |

51420 |

14021 |

X20Cr13 |

420S37 |

56C |

86020 |

2H13 |

3583 |

20C130 |

20Kh13 |

2303 |

420F |

51420F |

|

|

|

|

|

|

|

|

|

|

430 |

51430 |

14016 |

XBCr17 |

430S15 |

60 |

86020 |

H17 |

3583 |

10C170 |

12Kh17 |

2320 |

430F |

51430F |

14104 |

X12CrMoS17 |

|

|

|

|

|

|

|

|

430FSe |

51430FS |

14104 |

X12CrMos17 |

|

|

|

|

|

|

|

|

431 |

51431 |

14057 |

x22CrNI17 |

431S29 |

57 |

86020 |

2H17N2 |

|

|

201CH17N2 |

2321 |

436 |

51446 |

|

|

|

|

|

|

||||